Consultant - Screw compressorTHE FUTURE OF HYDRO POWER GENERATION

Globally, India stands 5th in the installed hydroelectric power capacity.

According to the report, ‘All India installed capacity (in MW) of power stations' published on 31st March 2020, India's installed utility-scale hydroelectric capacity was 46,000 MW. This accounted for 12.3% of its total utility power generation capacity.

In the future, it is estimated that India's hydroelectric potential shall reach up to 148,701 MW. Furthermore, it is said that an additional 6,780 MW from smaller hydro schemes which have capacities of less than 25 MW can be deemed as exploitable.

Apart from this, a total of 56 sites for pumped storage schemes with an aggregate installed capacity of 94,000 MW have also been identified.

Pump Storage Plants

At times of low electrical demand, excess generation capacity is used to pump water into the upper reservoir.

When the demand rises, the water is released into the lower reservoir through a turbine which generates electricity. This reversible turbine/generator assembly plays the dual role of a pump and turbine generator.

Once the evaporation losses from the exposed water surface and conversion losses are taken into consideration, close to 70-80% of recovery can occur. This technique is currently the most cost-effective means of storing large amounts of electrical energy.

Apart from generating hydroelectricity, pumped storage units find their application in pumping stations to supply river water for upland irrigation, industrial use and, generating drinking water.

Use of Compressed Air in Pump Storage Plants

In pump storage plants, the turbine and generator are operated in the reverse direction of the pump water from the lower reservoir to the upper reservoir during lean periods of power consumption.

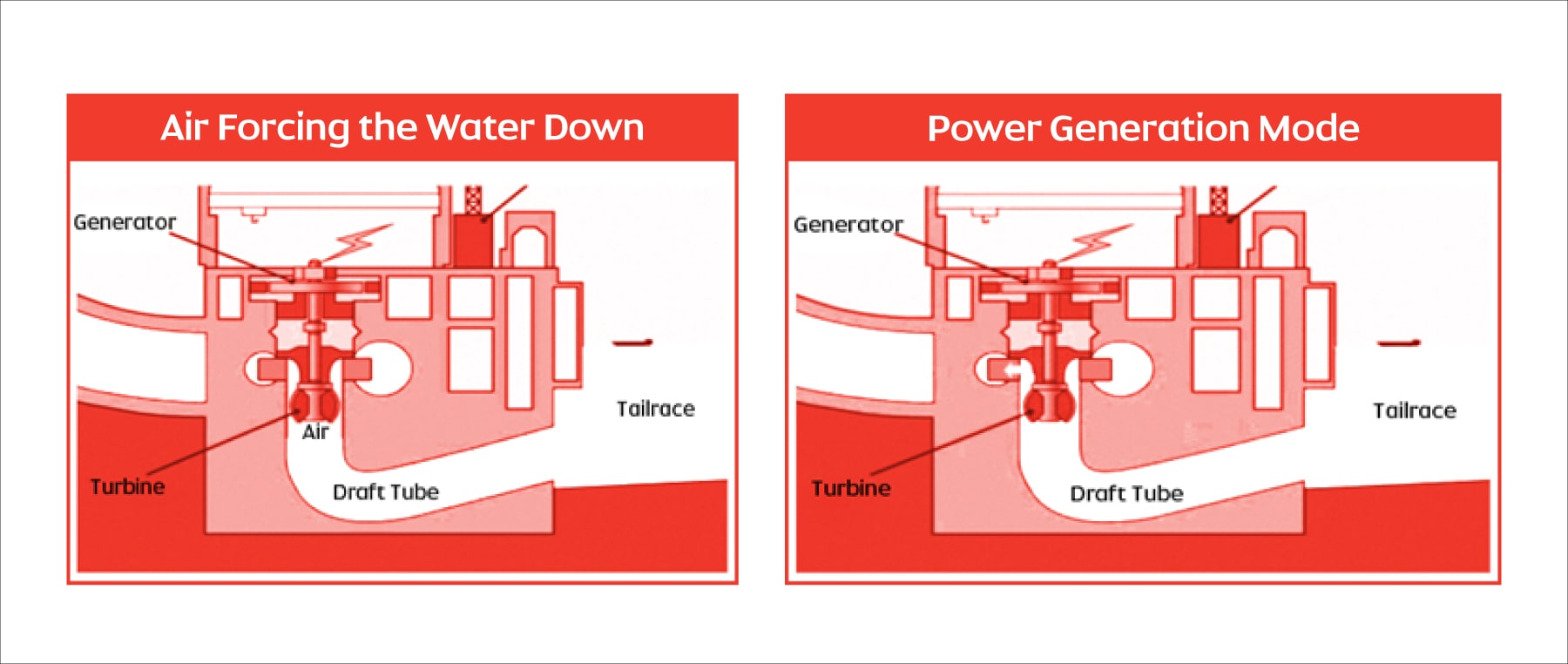

This is achieved by the Draft Tube Water Depression System.

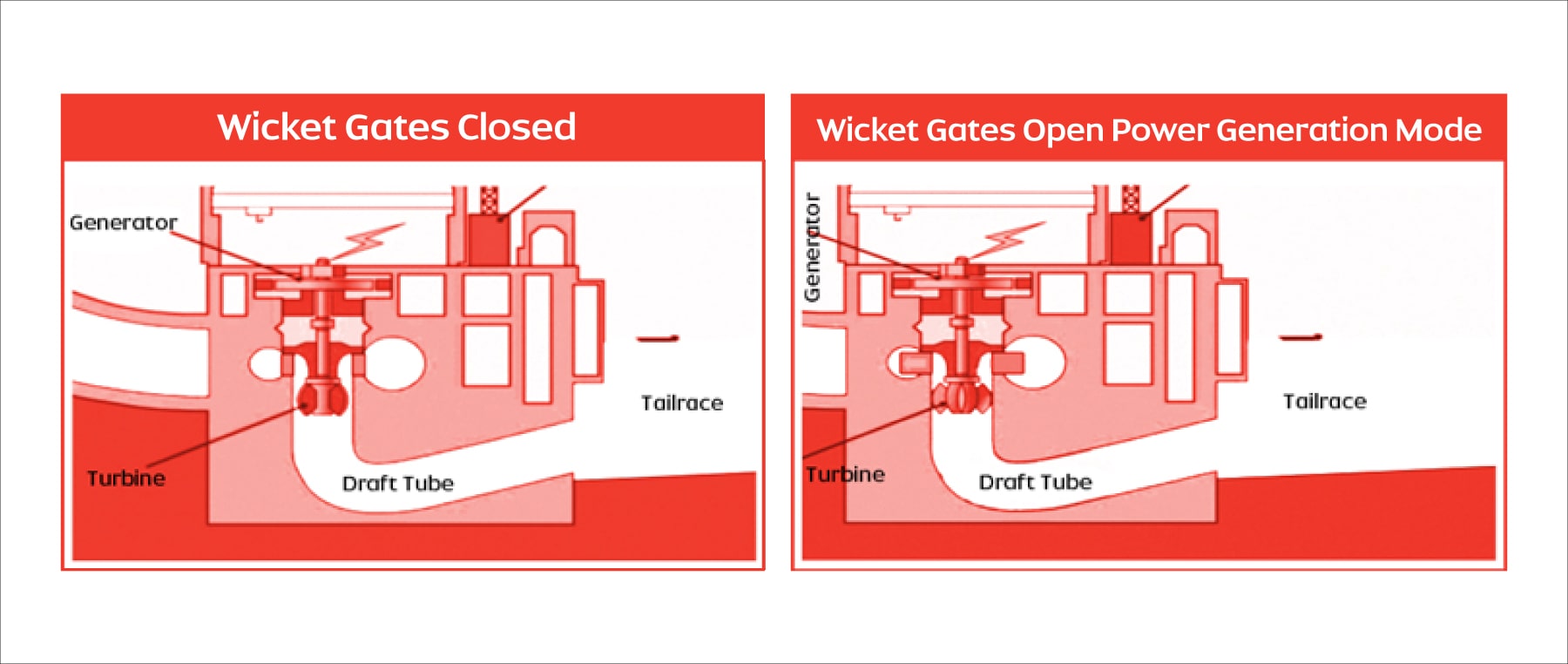

This process utilizes the high-pressure compressed air to depress the water below the runner of the turbine. Thereby, this compressed air allows the unit to motor with minimum power consumed from the system as it is spinning in the air as opposed to the water. Then, the wicket gates are opened to begin the pumping action as indicated below:

ELGi Sauer Compressors

ELGi Sauer is a joint venture between ELGi Equipments India and JP Sauer & Sohn Germany. This conglomerate caters to the needs of high-pressure applications in India and the subcontinent regions.

Over its 12 years, ELGi Sauer has developed a range of compressors suited for hydro power generation and has spearheaded installations with all the major hydro power companies in India and executed key projects locally and internationally.